Custom Sock Design – Guideline

This Post is a guideline about custom sock design, make sure you read this carefully to ensure we can knit out your design on the socks.

Custom sock design guideline

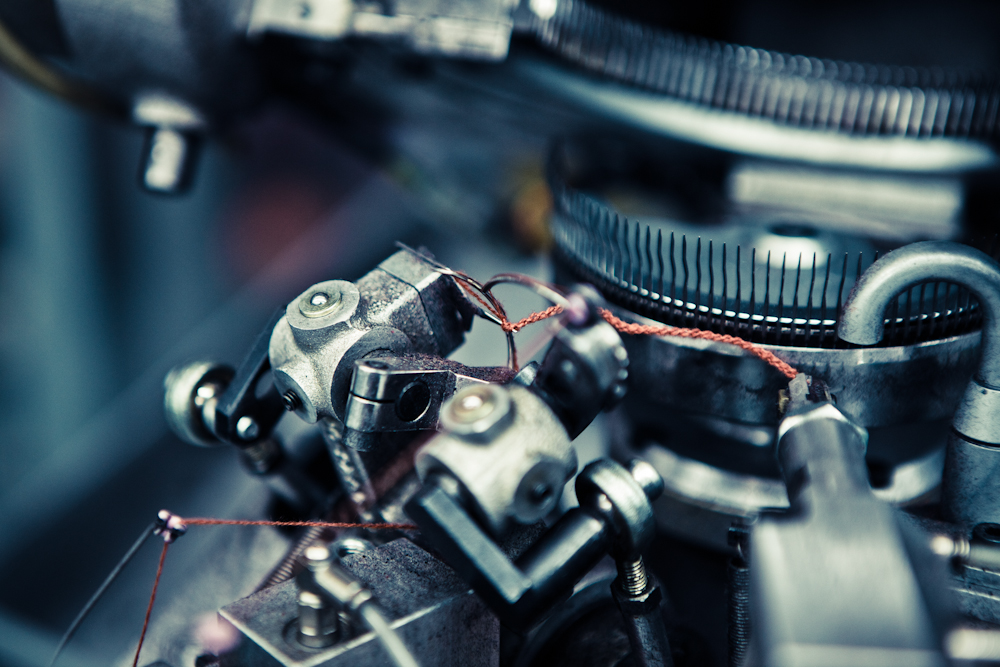

Designing for socks and other knitted goods is a very different process from designing for printed materials. The following is a brief guide for you to understand how socks are designed from the first pixel on the screen to the last stitch of yarn on the machine.

Setting up a knitting machine for a single sock design is similar to preparing an offset printer to produce a single design for a printed good. There is a good deal of preparation and set up before knitting begins.

1. Creating a pattern

Classic patterns such as argyles, polka dots, and stripes are designs that consistently execute well. We have the ability to knit a variety of different patterns. To ensure that designs like these knit out well, we have several tips.

1.1 Repeating patterns

In repeating patterns, it’s important to pay attention to the size of individual assets in the design. Keep in mind that designs on a sock stretch when worn. Too big, and the image will become very big as it stretches around the wearer’s ankle or foot. Too small, and the design will not render legibly on the sock.

1.2 Colors

The number of colors used in a design will affect the execution of the sock. The general rule is to use no more than 8 colors in a single design (including the background, heel, toe and top colors), and of those, no more than 5 colors can change through one horizontal line of the sock. Generally speaking, the more complex designs execute better when fewer colors are used.

Every time color changes, the yarn of that color is cut and tied off inside the sock. The fewer cuts, the better – designs that have frequent color changes are bulkier, don’t stretch as easily, and run a higher risk of knitting errors.

Color accuracy is one of the most important things combining design and production, below is a post on how to specify the right pantone TCX colors to ensure color accuracy:

2. Typography

Typography on socks: it is our suggestion that text on socks is kept to a minimum. A production file for knitting is prepared as a 168-pixel (for 168 needle machines) wide bitmap image. At this fixed size, the smaller the type, the poorer the legibility. If a logotype or byline must be included, we recommend placing it on the footbed of the sock. This ensures that the type will not be distorted by the stretch of the sock, and that the main pattern will not be interrupted.

3. Logos

Certain logos execute better than others when knit. Complex linework, color overlays, and gradients are very difficult to achieve and are generally best applied to custom packaging. Because of the fixed number of stitches in a sock, bold and simple shapes are typically best for sock designs.

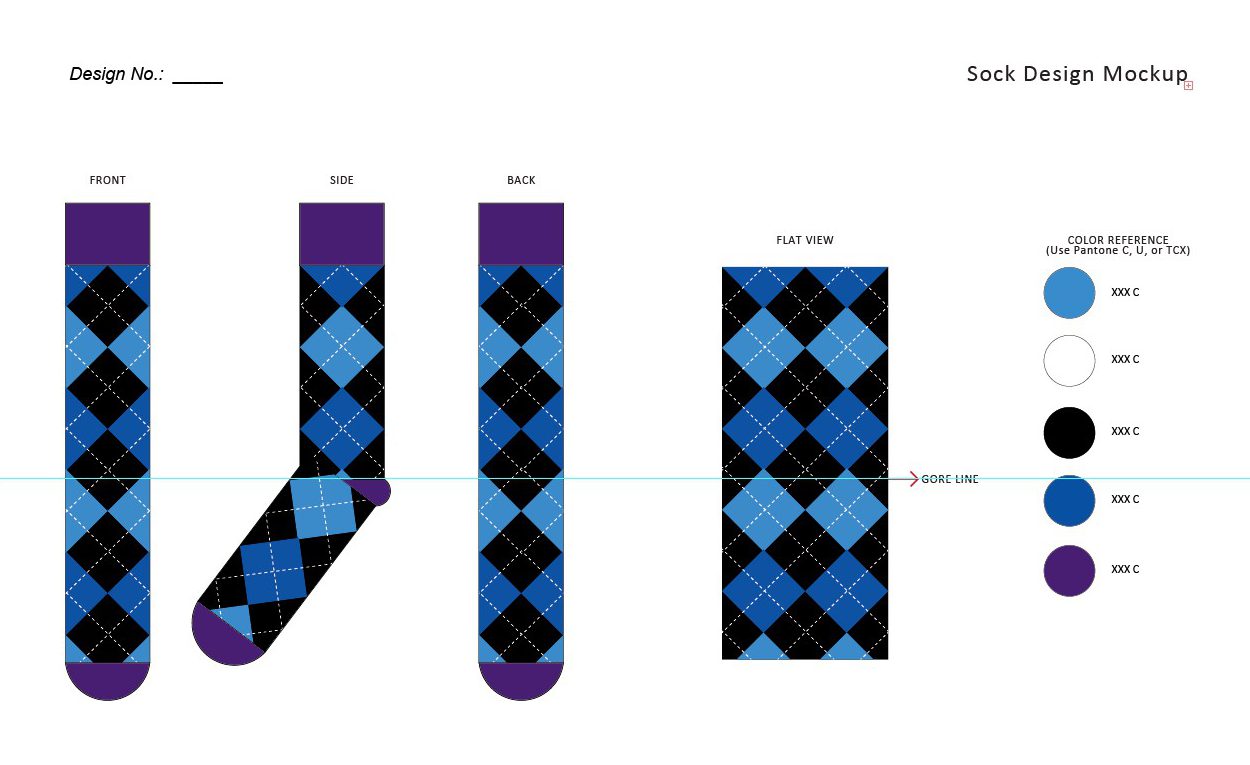

Final Step: Transferring a design to a production file

Creating knit-ready file typically involves transferring a vector design or otherwise into a production sized bitmap image, which will be done by our skilled programming team. Our knitting technicians use this file to program a knitting machine to transpose each individual pixel in the file to a stitch on the sock.

Once your design is finished, we will review it to ensure it meets the required technical specifications. Please send us your native files and PDF mockup, and we will suggest any changes to make sure it will be the best sock it can be.

Download the custom sock design template kit:

Besides of this custom sock design guideline, we have specially designed a design template kit for you including sock design, tag design, band design, check out the post below to download it!

Ready for Production?

Read our post about detailed socks manufacturing process:

Also, Contact us about socks manufacturing service.

Acknowledgement: Content of this post is revised from that shared by SOCKCLUB.

Hi! I’m very interested in working with you. I have read all your blogs and I was seeking on making an investment of 3,000 pieces ( 3 different models) but I wanted to know your costs. I’m from Mexico so if you could include transportation costs it would be great. Thanks

Hi Francisco, thanks for your interest and our sales representative will contact you soon.

Or if you have any other questions please feel free to leave a comment below.

Hello,

I read, understood and Love It. How do I begin?

Hi Steyn,

If possible please contact our sales representatives whose emails are listed on Contact page.

Thanks,

MeetSocks, one-stop custom socks service.

Thinking about starting my own designer sock company just looking for a company that can manufacture the brand and come up with great ideas and a high quality product

hey maybe we can help you, we happen to have a vertically integrated manufacturing socks company and have a great design team. My name is aleena Iqbal

my email address: [email protected]

Hi, I am very interested in your products. I am looking for a trustworthy provider to launch a product line, but I would like to have more information about your process and costs. How can I get in touch with your sales department?

Best,

Hi Pedro, please check our contact page at: http://www.meetsocks.com/contact/

O have tried sending several emails and have had no replies yet.

Please, could someone contact me? I have sent several emails and haven’t got a response.

Hi, Pedro,

Sorry for the inconvenience. Our colleague says that your planing custom sock order doesn’t meet our minimum of quantity. We are sorry to let you down.

Please understand that as we are a exporting sock factory, we can hardly accept small orders. I suggest you try those ones starting with less quantities.

Best wishes for your business!

Hi Meetsocks, I am sorry to hear that you don´t accept small orders! Could you recommend any companies that do? Kind regards, Siri

Is there a difference in the left and right sock if so what is it.

The left and right socks are not the same, they are usually symmetry.

It means that we need to program the knitting machine differently to produce the right and the left.

Hi, I’m interested in stsrting my own business and this is what I’m looking for, please send me more information for cost, thanks

Hi Jay,

Thanks for your contact.

Can you please send out an email to sales#meetsocks.com(with @ replacing #)?With your requirements and plannings.

Regards

You gave the complete Guidelines for socks design this process is very easy. Thanks for sharing this information with us.

Thank you!

Hi, how can i get in touch with you either phone or email

Hello MeetSocks.

What is your minimum order please? I have sent several emails without a response. Is there a better way of reaching you?

Hi, how can I get touch with you

Hello

My name is Bruce and I have recently purchased a few sock machines.I am looking for production for my machines.They are 132n single cylinder machines capable of 8 colors per course.I can make select terry garments as well as plain stitch.Stripes ,logos,etc.

I do the complete process myself from design to out the door.If anyone is needing small Custom Sock orders filled

Hey Bruce!

Sounds very interesting as it is very difficult to find small Custom Sock order manufacturers. Feel free to contact me and sharing some more information about it. 🙂

Hey Bruce,

sounds very interesting! Please feel free to contact me for further information about your set-up.

Hi Bruce,

I’m planning on create mu own line of socks.

I have an Idea what I want but I need more information.

Can you please contact me when you have the chance.

[email protected]

Hey Bruce! Can you reach back out to me if you are still in the small production business for socks?

Very intrested to read custom socks design guidelines. I am working with a company called Cotstyle, socks manufacturing company. I am searching for more socks product designs and patterns to introduce into Indian market. We actually from India and manufacturing men’s socks, women’s socks, kids socks which are perfectly suitable for Indian climate. our designers are working on stylish fashion socks in vibrant colours, made from finest yarns of 100% pure mercerised Egyptian and PIMA cotton. I have got good information here. Thanks alot. Your designs and colors are simply awesome. I like oil painting custom dress socks for men very much interested.

Hi! I’m very interested in working with you. I have read all your blogs and I was seeking on making an investment of 3,000 pieces ( 3 +different models) or more but I wanted to know your costs. I’m from Ajax Ontario Canada so if you could include shipping costs it would be greatly appreciated.

I’m looking for these components on my socks ( Cotton 73%, Polyamide 25%, Elastane 2%) and the design would be simple I would also want a logo at the top of the sock. Thank you

Hi Sergio,

Thanks for leaving a message, our sales team will contact you soon.

Best,

MeetSocks Team

Hi. I am a socks and pattern designer. I am really interested in designing socks. How can I get projects and work with you?

Hi, I am Nikoo and I’m a socks and pattern designer. I also know how to work with socks software. How can we work together? I can send you my portfolio if you are interested.

Hello Nikoo,

Please email to [email protected] with your designs. Basically we will make samples based on the designs and then we move into bulk production after your approval of the sock samples.

Regards,

MeetSocks Team